R&D and Production

Ningbo Exciton Technology Co., Ltd

Dedicated to becoming world class optical film solutions expert

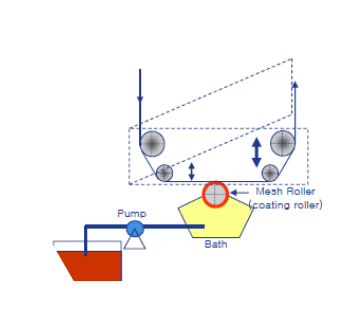

The micro-gravure coating roller is a reticulated roller with a general diameter between 20mm - 80mm.The method of which, is a kind of reverse and contacting coating, he rotation direction of the micro-gravure coating roller is opposite to which of the sheet material, and the sheet material is not pressed by the pressure roller. compared with the traditional gravure coating, the method has no back pressure rubber roller, so that potentially adverse factors caused by back pressure roller will not be emerged.

Characteristic:

1. The micro-concave roller is small in diameter and light in weight. It can be coated with different amount of coating. It is convenient to replace the micro-concave roller and does not occupy space for storage.

2. thin coating can be applied to thin materials. Because there is no pressure on the back pressure roller, there will be no offset, wrinkle and other defects. At the same time, the edge of the sheet can also be glued instead of worrying that the glue is applied to the back pressure roller to affect the coating.

3. reverse coating can obtain relatively flat coating, and the coating quantity is evenly distributed.

4. because the scraper is lightly contacted with the roller, the abrasion of the scraper and the net roller is very small.

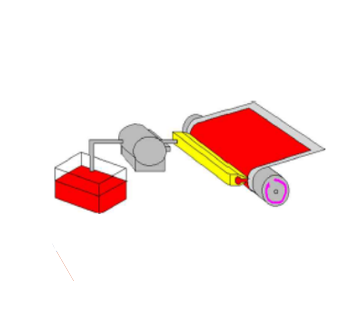

Coating machine is a high-precision coating method, coating glue from the memory through the supply pipeline pressure to the nozzle, and make the glue from the nozzle ejection, thereby transferring to the coating substrate.

Features:

1. The micro-concave roller is small in diameter and light in weight. It can be coated with different amount of coating. It is convenient to replace the micro-concave roller and does not occupy space for storage.

2. thin coating can be applied to thin materials. Because there is no pressure on the back pressure roller, there will be no offset, wrinkle and other defects. At the same time, the edge of the sheet can also be glued instead of worrying that the glue is applied to the back pressure roller to affect the coating.

3. reverse coating can obtain relatively flat coating, and the coating quantity is evenly distributed.

4. because the scraper is lightly contacted with the roller, the abrasion of the scraper and the net roller is very small.

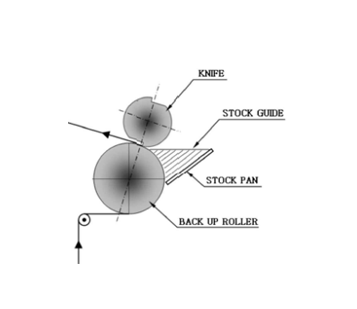

The comma scraper roller is characterized by a combination of blade scrapers and roller scrapers. The influence of glue thickness is smaller than that of blade scraper. The coating thickness is relatively easy to adjust and can be coated with high viscosity glue. When the width is large, it can be adjusted horizontally.

Features:

1. The scraper has high strength, high hardness and small error of edge straightness. Pneumatic fine-tuning mechanism can be used to adjust and control the position of the scraper. The coating quantity is controlled accurately and the scraping precision is higher.

2. Suitable for medium and high viscosity coating fluid, can be coated with a thicker coating, coating fluid from top to bottom flow between the blade and film, can be fully used, there is no waste of glue phenomenon.